For most of the photos on this page, you can click the image for a larger picture.

|

This shows the joint between the two halves of the cylinder pattern. Whilst there is no global specification for colours used in pattern making, Tony is using colours available from our pattern making suppliers along with the pattern colour code from BHCET in India.

Having discussed black in the previous photo, now we can look at green. This colour will be used for joints and seats of various parts including 'loose pieces' and loose core prints. I do not normally colour up during the making of a simple pattern but because Tony is not working on the cylinder pattern continuously and for educational purposes for the reader, Tony has decided to do so. The end shown in green denotes the joint between the two halves of the cylinder pattern and eventually will be a tenon type, albeit round, a sort of plug and socket. The next half of the cylinder will have the internal part of the joint.

Tony has one more small job to do before he turns down the centre of this half of the cylinder which is to turn the two ends of the blank down to finished dimensions to enable him to work with a template on the cylinder banding. |

|

This shows the start of turning the banding and flange. Between the two banding blanks is the outside of the cylinder body and this is down to just above finished size. Tony is now close to finishing this half of the main motion cylinder. The next stage, while it is still on the lathe, is to apply filler where necessary and sand to a very smooth surface all over. |

|

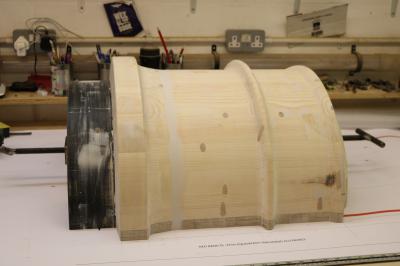

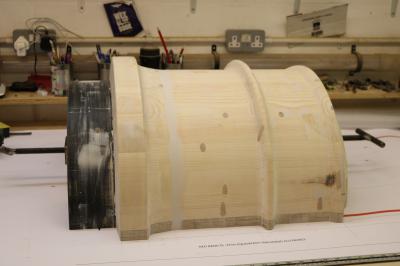

Tony has now finished the turning of the first half of the main cylinder pattern. The 45 degree angle on the right hand side of the pattern with the green face is the plug that will engage with the socket on the second half of the pattern. Each of the 2 patterns also divides horizontally - you can see this split in the middle of the pattern as indicated by the plywood. The circumferential bands are part of the cylinder casting. Tony now has to do the whole thing again with the second half of the main cylinder pattern. Even with a dust extraction system, a large amount of sawdust has to be cleared up! |

|

Having finished the first half of the main cylinder pattern, Tony has started work on the second half. The first job is to use a power planer to take off all of the plank edges with a power planer. He will need to clean up a bit after the planing before he progresses any more. |

|

Now we can see the 2 halves of the main cylinder pattern. The first section on the lathe can come off now to be replaced by the second. For the first half, Tony and Keith will be working together on the items needed to complete it. |

|

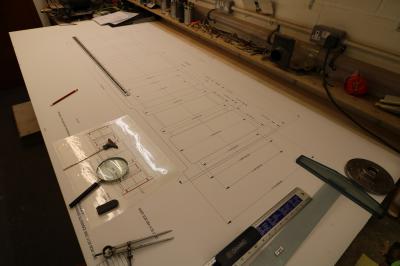

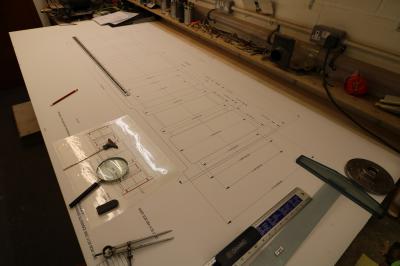

September 2018 - As a long, hot Scottish summer closes, Tony can get back on the indoor jobs. The picture shows the half cylinder pattern (half of the complete job) sitting on top of a full size drawing to confirm all dimensions are correct. Tony says "this shows the real usefulness of these full size drawings and confirms that I'm not building up a cumulative error". |

|

Finally, the turning of the motion cylinder is nearing completion. The female joint is now formed to mate with the other half of the motion cylinder and for interest, the oak dowel pins which help to hold everything together are clearly seen. When the yellow pine blanks were formed, the initial layered construction was glued and screwed and when the glue had set, the screws were replaced by glued dowels to preserve the strength of the joints and not cause mayhem with my turning chisels. |

|

Two final long shots of Hengist's motion cylinder section of the overall pattern just prior to its removal from the lathe. The next 'Hengist' job on the lathe will be the first half of the valve cylinder.

The next job going on to the lathe will be a pattern for an air pump body for the 'Maid of the Loch', a steamship on Loch Lomond. |

|

|

|

Tony has now completed checking the motion cylinder so his attention now turns to the valve cylinder. Once again, he's working on top of one of Keith's drawings, scaled for shrinkage, and is in the process of setting out the measurements for the two parting boards. The parting boards allow the pattern to be split into 2 semi circular halves which will allow them to be extracted from the sand moulds. The construction will follow the methods used in the motion cylinder except this blank will not be hollow. It will be turned in two halves, like the motion cylinder, to enable him to get it between the lathe centres. |